How to Engage

Our process

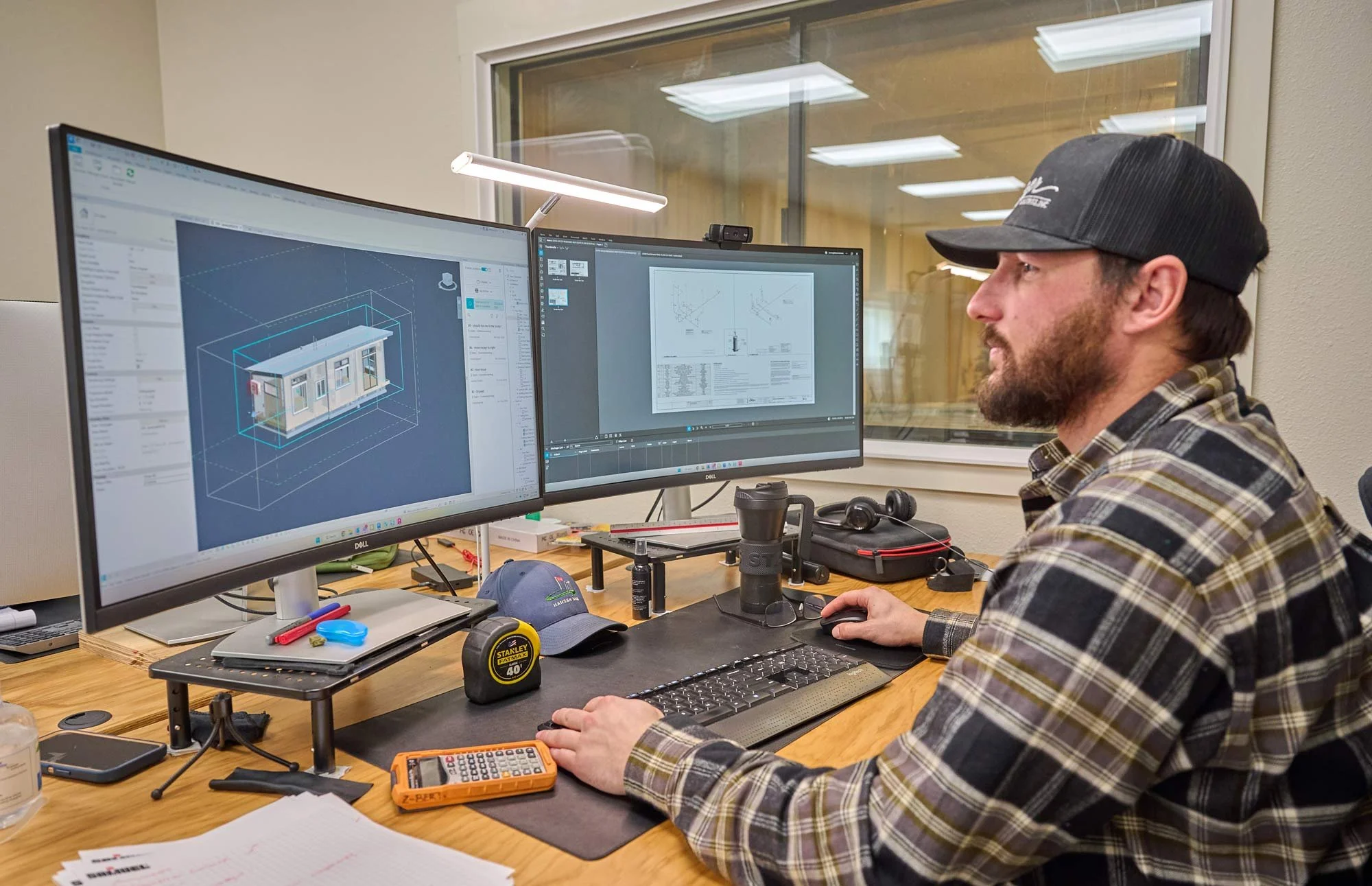

Working With Blazer

Blazer Modular Construction partners with architects, modular building dealers and general contractors located in your region who coordinate design, budget, schedule, permits and sitework. This allows us to serve broader markets in the Western United States, Hawaii, and Alaska—while our crews stay close to home and family.

FEASIBILITY AND PROJECT TEAM

Blazer can recommend qualified firms with experience in your region and building type and will work closely with your team to assess viability for modular construction.

Your dealer or contractor becomes the primary point of contact, coordinating with architects, engineers, and the site crews. Blazer joins this team as your modular builder.

Services and project scopes vary between architects, engineers, dealers, general contractors and modular builders. Be sure to carefully review the entire scope of work for your project.

DESIGN AND PRICING

Your team works with Blazer to design and approve the modular building, pricing, and schedule. Blazer provides detailed input to ensure your specifications are met within the parameters of modular construction.

Our objective is for project success on behalf of the entire team.

WE BUILD. THEY DELIVER.

Blazer constructs your modules at the factory in Aumsville, Oregon while the site team prepares foundations and utilities. We ensure every module meets the highest standards before leaving our factory. Your dealer or contractor then oversees delivery, installation, and site completion. Throughout the process your team is encouraged to visit the factory, meet with Blazer and inspect the buildings.

The Details

Modular construction shifts big decisions to the front end. Locking in design and budget early allows us to avoid delays in production.

Schematic Design

Your architect works with Blazer to develop schematic drawings, which typically include floor plan, room layout, preliminary code review for occupancy and use requirements, and aesthetic features such as roof pitch, siding, windows, doors, and interior finishes.

For predesigned plans we’ll work with the original designer and your contractor to define scope of work, update design elements, code requirements and budget pricing.

DESIGN Development

This is where the design comes together. Room layouts and details are confirmed, including finishes, accessories, fixtures, mechanical, electrical and plumbing. System functions are thoroughly reviewed.

Deliverables at this stage:

Detailed drawings and specifications

Updated pricing

Suggestions for value engineering if needed

Once updates have been made and approved, you’ll sign off on pricing and scope. This “design lock” allows us to schedule final engineering, submittal for permits, purchasing and production.

Engineering & Construction

Blazer prepares required documentation for approvals of the modules including:

Structural engineering (in-house or contracted)

Mechanical-Electrical-Plumbing (MEP) design (plus sprinklers if required)

Code compliance review and reports

Factory submittals to State or Third-Party reviewer

Upon State or Third-Party approval, the modular construction plans will be issued to the contractor for submittal to the local jurisdiction.

Production & Inspections

Our manufacturing floor blends the best of modular and site-built practices.

Framing components are built at specialized stations, then assembled into volumetric modules. Each module is leveled and bolted together to ensure flawless fit once delivered.

Blazer maintains rigorous quality checks throughout construction. Our Quality Assurance team inspects framing, mechanical, electrical and plumbing systems, insulation, finishes, and energy features to ensure installation meets or exceeds standards. State or third-party inspectors must approve every module at cover and final stages before the modules leave the factory.

Process FAQs

Tips & Tricks for Building your project with Modular

-

Although Blazer’s factory capacity and experience allows for some flexibility for scheduling and expedited project delivery, design, scope and pricing decisions must be made prior to final engineering, purchasing and production.

Blazer provides detailed schematics, design development, construction drawings, and specifications that the customer must review and sign at each stage of the design process.

Once the construction drawings have been approved, a ‘design lock’ is put in place. Changes made after this design lock will typically cause schedule delays and incur change order fees and costs.

Factory scheduling: modular builders often schedule many projects at one time. Blazer has capacity for nearly forty projects under construction in a single timeframe. Delays in design decisions and plan approvals lead to inefficiencies in the factory, which add costs to projects. Much of this cost is absorbed by the factory through lack of productivity on buildings, carrying costs of materials, or delays in purchasing materials. Blazer makes every effort to keep your original schedule request. When delays happen, Blazer first looks to shift the project schedule one week at a time. When production scheduling is tight your project could be delayed for weeks or months.

Other factors that affect schedules:

1. Material procurements;

2. State plan reviews.Bottom line: projects with all information, pricing, engineering and submittals approved take priority over projects that require change orders or experience delays due to decision making, material procurement or complex code issues.

-

To control costs, it’s essential that you and your team of designers, contractors and builders closely review the entire project scope to reduce service and pricing overlap, or ensure that essential (and costly) details are covered.

-

Carefully choose a contractor that understand and supports the process for incorporating modular construction into the project and is willing to collaborate closely with the design and construction teams.

-

We are here to serve you (the customer) and your team. Do not hesitate to communicate with the team, schedule meetings, or visit the factory.

-

Blazer prices the modular scope per your specifications and state and local code requirements. We understand that design decisions take time, and that you’re making a big investment in this project. We want you to be happy with your project, and can process change orders up to the point of design lock. After this, change orders include fees for extra project management, drawing revisions and delays for plan reviews, purchasing and production.

-

Modules must fit within transport parameters. Generally, a module should remain under 16’ width, 74’ length and 13’-2” height. Over the years Blazer has adopted (or developed) innovations that allow for design flexibility such as hinged roofs, roof modules, or site-installed wall or roof panels.

-

Do:

Work closely with a builder or designer experienced with modular construction.

While anything may be had for a price, many ideas can be challenging and costly. Features such as pop-outs, excessive glazing, complex roof or wall designs, and double-story vaulted ceilings may increase expenses.

Keep in mind that Blazer has been in the business of modular construction for six decades and has seen or tried many ‘new and innovative’ ideas. Modular construction is not new, revolutionary or ‘as easy as building with Legos.’ It’s not rocket science; however, no construction is inherently easy, particularly in areas with stringent code requirements for energy efficiency or seismic engineering.

-

The most successful modular construction companies survive by adjusting to the markets and growing organically. Blazer believes there is opportunity to utilize technology, process improvements and smart design to offer a broad range of products and services to customers who demand variety in aesthetics and building layout. We focus on standardization of construction details and engineering so that we can offer more options. Our curated product line offers a selection of designs that work well for modular construction.

Need Help Getting Started?

We’re happy to consult on modular feasibility, recommend trusted design partners, or help scope your next project.